Energy Conservation by UVA Research Labs in 2018

By Christine Alencar, Green Labs Specialist, Office for Sustainability

There are approximately 520 lead researchers, or “Principal Investigators”, working on the University of Virginia’s main campus in Charlottesville. This year, 45 of those researchers participated in Green Labs programs to lower their energy intensity, some of them doubling or tripling their efforts.

The Office for Sustainability (OFS) is excited to report the results of this year’s energy-saving initiatives in research labs. The International Lab Freezer Challenge, UVA’s Pilot Lab Program, and the Energy Impact Tracker in concert with the fall semester’s Shut the Sash Competition (for chemical fume hoods) will together remove approximately 68 metric tons of carbon dioxide equivalent (greenhouse gas emissions) from our University’s carbon footprint, an amount equal to almost seven American homes worth of energy and valued at approximately $10,600 in utility costs per year.

A closer look at the International Laboratory Freezer Challenge

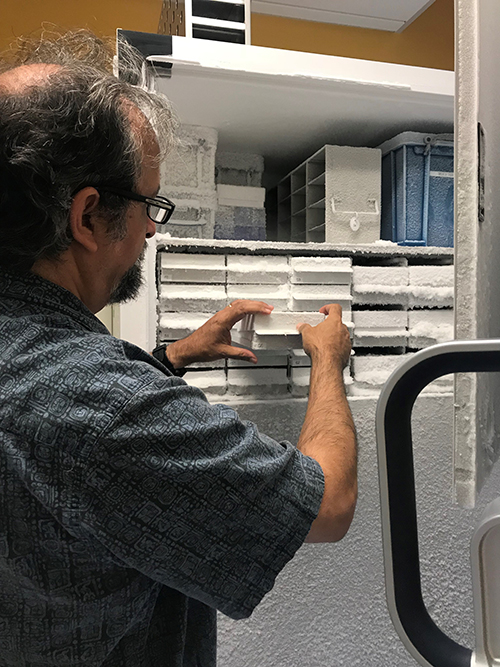

One ultra-low temperature (“ULT”) freezer set to -80°C can use as much energy as a single American home. Multiply that by the hundreds of freezers at UVA, and one can easily envision the energy footprint of several suburban neighborhoods contained just within our research labs. Every spring semester, the non-profit organization My Green Lab organizes The International Laboratory Freezer Challenge to encourage friendly competition between institutions and universities in their efforts to reduce the energy demand for cold storage. Competitors earn points by reporting the number of samples consolidated or discarded, warming their temperature setpoints (ex. switching from -80°C to -70°C), and upgrading to more efficient models, among other actions.

Academic category winners were the University of Illinois Urbana-Champagne, Colorado State, and the University of Colorado Boulder, with UVA placing fourth. The Office for Sustainability and Green Labs Program rewarded top performing labs from our own campus. This year, Dr. Anthony Spano in the Biology Department placed first, conserving over 9,000 kWh / year. Dr. Spano decommissioned two outdated units, consolidating all his research materials into one new Energy Star lab freezer. When asked about his experience competing, Dr. Spano described his newly organized space as “[…] excellent compared to what was there before,” stating that he was “relieved” after going through the inventory process. Second and third place went to the Zong and the Hammarskjöld – Rekosh labs in the Microbiology, Immunology, and Cancer (MIC) Research Department. Altogether, 21 participating labs will save approximately 50,000 kWh / year, or close to two and a half American homes!

A closer look at the Pilot Lab Program

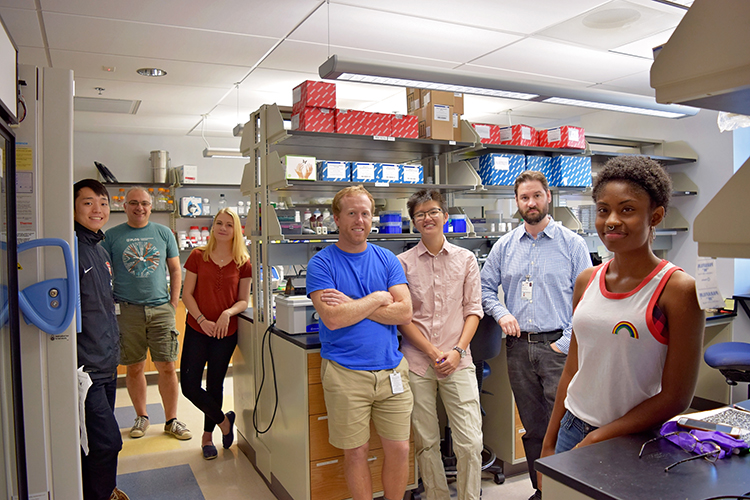

In late 2017, OFS initiated a comprehensive study of energy intensity and mitigation strategies in UVA laboratories. The Pilot Program Team was comprised of an Energy Engineer and a Green Labs Specialist who together directed the program in collaboration with three partner research labs and their respective Green Leaders (typically a Lab Manager). Each partner lab was unique in its makeup and research focus, the first hailing from the MIC Department on the seventh floor of Pinn Hall, the second from the Center for Public Health Genomics in the West Complex, and the third from Chemistry Department in the Chemistry Building.

Throughout the spring and summer of 2018, the labs were outfitted with LED lights, some received dimmers or occupancy sensors, and all received detailed Green Labs training to enhance sustainable research operations at the bench. Green Leaders then worked closely with OFS to develop a custom action plan for becoming a Certified Green Lab. Ultimately, the labs’ perspectives greatly contributed to the newly designed Green Labs Certification that any lab at UVA can achieve. The certification was designed to be flexible, approachable, and beneficial for research.

Simultaneously improving the built environment (ex. energy-meter application, LED lighting, low flow aerators on faucets) and educating lab occupants on sustainable research strategies (ex. maintaining inventories, performing maintenance on freezers, changing temperature settings, shutting the sash) allowed the Program Team to explore what is possible when a holistic plan is implemented. After its completion in the fall of 2018, the Pilot Lab Program will save an estimated 18,800 kWh / year, with two labs achieving Silver Certification and one lab achieving Gold Certification. Working closely with lab personnel provided invaluable perspective on which changes have the greatest positive impact on research, and OFS plans to expand the Pilot Lab Program across UVA’s campus.

A closer look at the Energy Impact Tracker and fall Shut the Sash Competition

Used for raising awareness that buildings are major contributors to carbon emissions, Energy Dashboards have a long history in sustainability outreach and education. The most effective Dashboards provide immediate solutions for building occupants to reduce energy consumption and encourage continued interaction with the Dashboard. For example, Harvard University has found success in implementing outreach programs designed to run in parallel with informational Dashboards. Their “Shut the Sash” chemical fume hood competitions prompt research labs to set a sash position goal and researchers can track their progress on the electronic dashboard in real time.

Seeing success at other institutions, OFS and other contributors in Facilities Management (FM) created UVA’s The Energy Impact Tracker for the Physical and Life Sciences Building (PLSB). Home to Biology, Chemistry, and Physics research labs, PLSB houses a diverse research community. Being a newer building, all chemical fume hoods are equipped with sash position sensors, allowing FM to track how open or closed the hoods are in real time. An open sash is generally correlated with higher energy consumption, while a closed sash not only lowers the carbon footprint of the building, but protects lab occupants from potentially dangerous vapors or flammable chemicals. Every October, UVA’s own “Shut the Sash” competition rewards labs who participate by setting an improvement goal or filling out an informational questionnaire about chemical fume hood best practices. This year, every lab that set an improvement goal in PLSB met or exceeded that goal, and overall there was a 49% improvement in sash position that will result in $5,500 projected utility savings in PLSB! Visit the Sustainability Blog to learn more about last year’s competition achievements.

Green Labs is looking forward optimistically at the many opportunities for expanding sustainability in UVA research spaces. Spring 2019 will welcome our third Freezer Challenge with a goal of examining current ULT setpoints at UVA. In addition, OFS will begin scaling successful components of the Pilot Lab Program to the greater research community, and labs achieving Certification will be rewarded for their contribution to a greener research environment. Does your lab want to get Certified? Email [email protected] to get started!